3D Printing for Mars Habitat

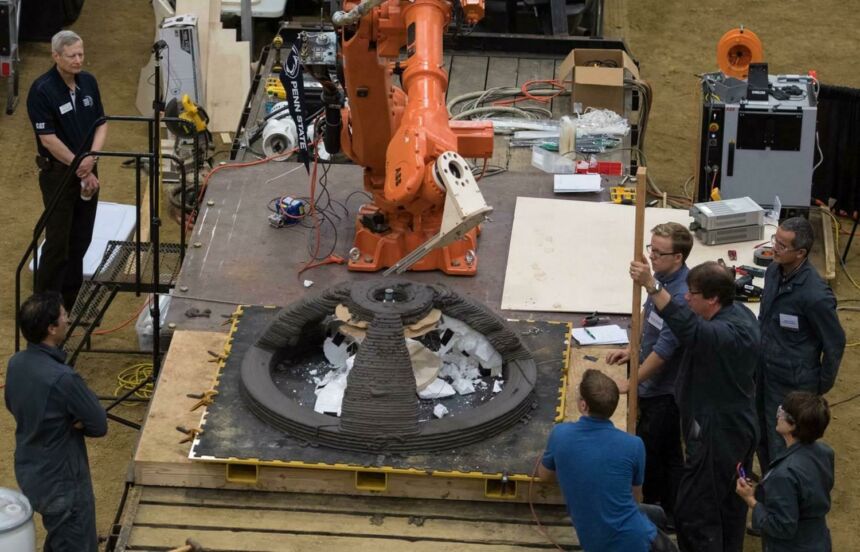

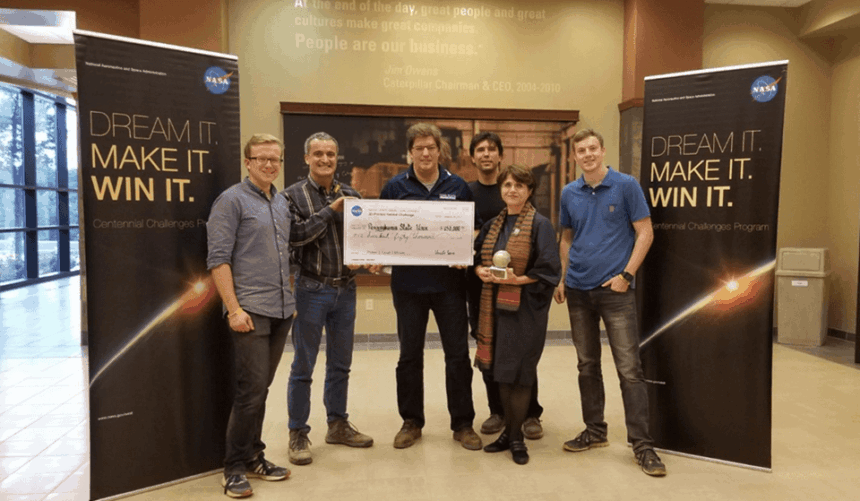

The project focuses efforts in three areas: development of a novel concrete formulation, development of the 3D printing processes, and design and development of the overall 3D printing system necessary to print large structures.

The production of the geopolymer binder used in the formulation of the concrete designed by the team does not emit carbon dioxide into the atmosphere, unlike the production of Portland cement (the most common type of cement). Current expertise in 3D printing, also called additive manufacturing, is leveraged to transfer expertise with smaller-scale printers and their associated processes to the large-scale printing of concrete.

The project is based on previous research aimed at developing functionally-graded materials and verifying the possibility of designing and constructing seamless buildings, which can have a significant impact on architectural language and building processes. The project aims to develop additive manufacturing technology to 3D print habitats using a specially formulated concrete made from materials that can be found on Mars but can be applicable on Earth.

Gallery