May 12, 2020

School of Theatre faculty, staff and students producing protective masks

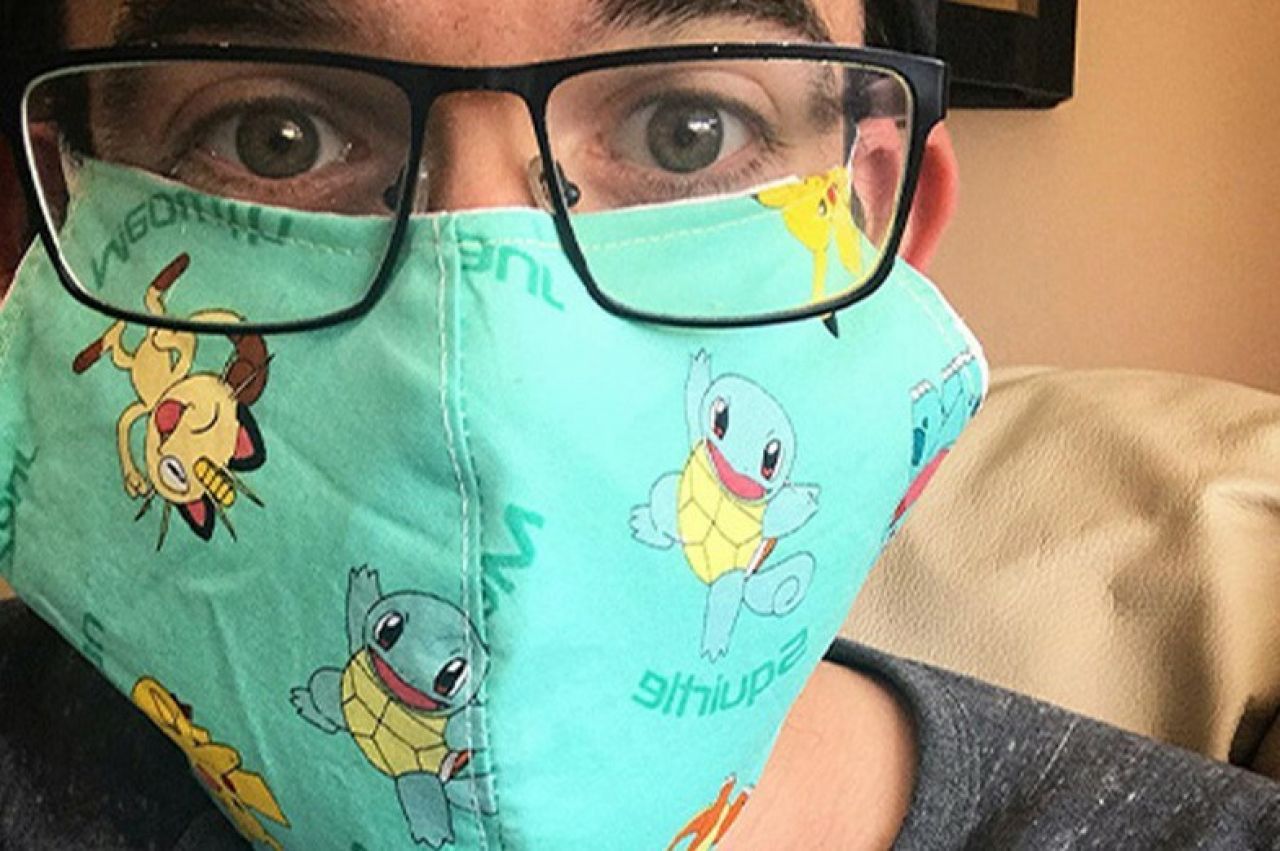

To help meet the demand for the personal protective equipment (PPE) needed to battle COVID-19, faculty, staff and students from the School of Theatre’s costume design program are pooling resources and employing their unique skillset to produce protective cloth masks.

Led by faculty members Charlene Gross and Laura Robinson, the manufacturing effort has produced more than 200 reusable cloth masks in about one week, and production is ramping up, according to Robinson.

Following the World Health Organization’s recommendations, the group is producing rectangular and fitted cloth masks that are held in place with either elastic or cloth ties.

Joining Gross and Robinson in production are first-year graduate students Keagan Styes, Jessica Hill and Tyler Phillips; costume shop draper Amanda Ferg; and costume shop supervisor Diane Toyos.

Except for Phillips, who is producing and distributing in Chicago, the team is operating in the State College area and masks have been distributed to local community organizations such as nursing homes. The supply at local hospitals is intact, according to Gross, but the group has offered production to medical facilities if the need arises.

The effort began when Styes, who has three immediate family members who are nurses practicing in her hometown of Austin, Texas, received a call from her mother.

“She called me in a panic and told me that they were running out of masks,” Styes said. “My mom and my younger sister aren’t on the front lines, but my mom’s husband is, and I told her I would get fabric and start immediately. I’ve sent all that I have made to Austin and I’ll keep going.”

Adjusting to the new academic normal, Styes thought the production could count for graduate assistantship hours and reached out to Robinson.

“My answer was ‘absolutely,’” Robinson said. “While I don’t think any of us ever considered our sewing skills being used for this, as soon as it was mentioned things just clicked and it was clear that this was our way to contribute to society in a time of need.”

With the seed of an idea, Robinson contacted Gross and the two made quick decisions to organize a team, gather resources and within three days the production was in full bloom.

As directives on the University Park campus closure were being released during the week of March 16, and after receiving approval from College of Arts and Architecture administration, the two returned to campus, followed health protocol and loaded a shopping cart with tightly woven cotton material and elastic for the team to use.

Locally manufactured masks are being delivered to Gross’ home in State College and WHO recommendations on handling of the masks are being followed. From there, the masks, which include sterilization instructions, are being distributed locally.

“Because of the support of the University and College of Arts and Architecture, we are prepared to continue this effort for as long as we need to,” Gross said. “As we were getting this started the idea was simple—we each have the skills, resources and machines needed to make these masks, so let’s get going.”

In addition to the productions of the masks, the team has volunteered their time and skills to Penn State’s Manufacturing And Sterilization for COVID-19 (MASC) Initiative, which aims to leverage Penn State’s research enterprise to innovate potential solutions to address the healthcare needs caused by COVID-19.

If you would like to contribute to this effort, contact Gross at cag83@psu.edu. At this time, due to safety concerns, donations of materials to the costume design team are not being accepted.